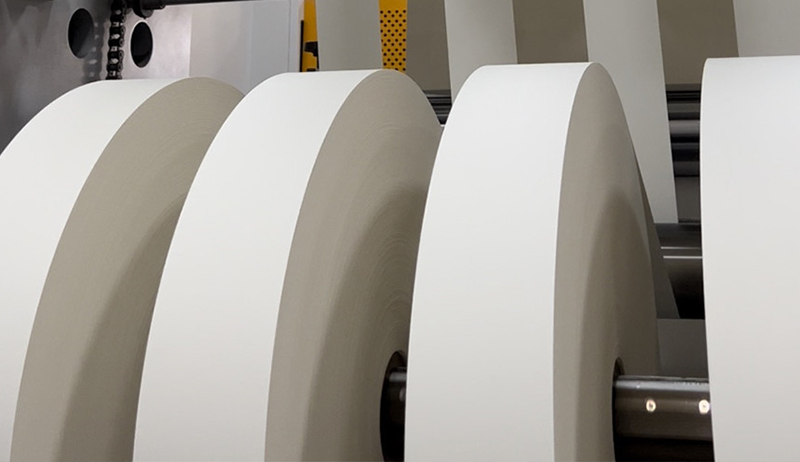

Stacking, storage and maintenance of coated kraft paperboard: a comprehensive guide to ensure worry-free quality

1. Scientific planning of stacking methods

The stacking method is one of the key factors affecting the quality of coated kraft paperboard. Reasonable stacking can not only effectively prevent the deformation and damage of the paperboard, but also improve the utilization rate of storage space.

Stack flat and avoid folding

Coated kraft paperboard should be stacked as flat as possible to avoid creases and damage caused by folding or overlapping. When stacking, ensure that there is a certain gap between the paperboards to avoid keeping the same bending position for a long time to reduce the occurrence of creases. At the same time, the stacking height should be moderate to avoid excessive height causing the bottom paperboard to be compressed and deformed.

Classified stacking and clear labeling

For coated kraft paperboards of different specifications, thicknesses and uses, they should be classified and stacked, and clearly labeled. This helps to quickly identify the required paperboard, reduce the time of searching, and avoid confusion and damage between different specifications of paperboards.

Use pallets or shelves

When stacking coated kraft paperboard, pallets or shelves can be used to support the paperboard to reduce direct contact with the ground. This not only prevents the influence of ground moisture on the cardboard, but also improves the stability and safety of stacking.

2. Careful construction of storage environment

The storage environment is crucial to the quality of coated kraft paperboard. A dry, ventilated and temperature-appropriate storage environment can effectively extend the service life of the paperboard.

Keep dry and avoid moisture

Coated kraft paperboard is susceptible to moisture, so the storage environment should be kept dry. You can choose to install a dehumidifier or place a desiccant in the warehouse to reduce humidity. At the same time, the walls, floors and ceilings of the warehouse should be checked regularly for leaks, and repaired in time to prevent moisture from invading.

Good ventilation and avoid confinement

The warehouse should maintain good ventilation to avoid air stagnation caused by a confined environment. You can open windows for ventilation regularly, or use equipment such as exhaust fans to accelerate air circulation. This helps to reduce the temperature and humidity in the warehouse and keep the cardboard dry and stable.

Appropriate temperature, avoid extremes

The temperature of the storage environment should be kept within a certain range to avoid overheating or overcooling. Generally speaking, the temperature between 15~25℃ is more suitable. Too high a temperature may cause the strength of the cardboard to decrease, while too low a temperature may make the cardboard brittle. Therefore, the temperature control equipment of the warehouse should be adjusted according to the actual situation to ensure that the temperature is appropriate.

3. Careful implementation of maintenance measures

In addition to the stacking method and storage environment, meticulous maintenance measures are also an important part of ensuring the quality of coated kraft paperboard.

Regular cleaning and stain removal

During storage, coated kraft paperboard may be stained with dust, oil and other stains. Therefore, the surface of the paperboard should be gently wiped with a soft brush or dry cloth regularly to remove stains and dust. Avoid using a wet cloth or detergent containing chemicals for cleaning to avoid damage to the paperboard.

Anti-insect and anti-moth, protect the paperboard

Coated kraft paperboard is an edible object for insects, so measures should be taken to prevent pests. An appropriate amount of insect repellent or mothballs and other items can be placed in the warehouse to repel insects. At the same time, the warehouse should be checked regularly for signs of pests, and timely measures should be taken to deal with them.

Regular inspection and timely treatment

Regular inspection of stored coated kraft paperboard is an important measure to ensure quality. A comprehensive inspection can be carried out monthly or quarterly, including the appearance, strength, printing adaptability and other aspects of the cardboard. If the cardboard is found to be deformed, moldy, discolored or damaged, timely measures should be taken to deal with it, such as replacing the damaged cardboard, adjusting the storage environment, etc.

Avoid placing heavy objects on the cardboard to protect the integrity of the cardboard

During storage, avoid placing heavy objects directly on the coated kraft cardboard to avoid crushing or deformation. If you need to use shelves or pallets to support the cardboard, ensure that the load-bearing capacity of the shelves or pallets is sufficient, and check their stability and safety regularly.

English

English Español

Español